Een uitgekiend modulair basisconcept gecombineerd met zijn extreem robuuste en compacte ontwerp geeft de gebruiker maximale flexibiliteit en veelzijdigheid. Het systeem is vrij schaalbaar in lengte en kan worden aangepast aan alle machineformaten en inbouwsituaties. Hierdoor is het mogelijk om een LEDcure unit op verschillende posities op een machine te gebruiken. In combinatie met tientallen jaren ervaring in op maat gemaakte machine-integratie, zorgt het compacte ontwerp ervoor dat de gebruiker op elk moment toegang heeft tot belangrijke delen van de drukpers.

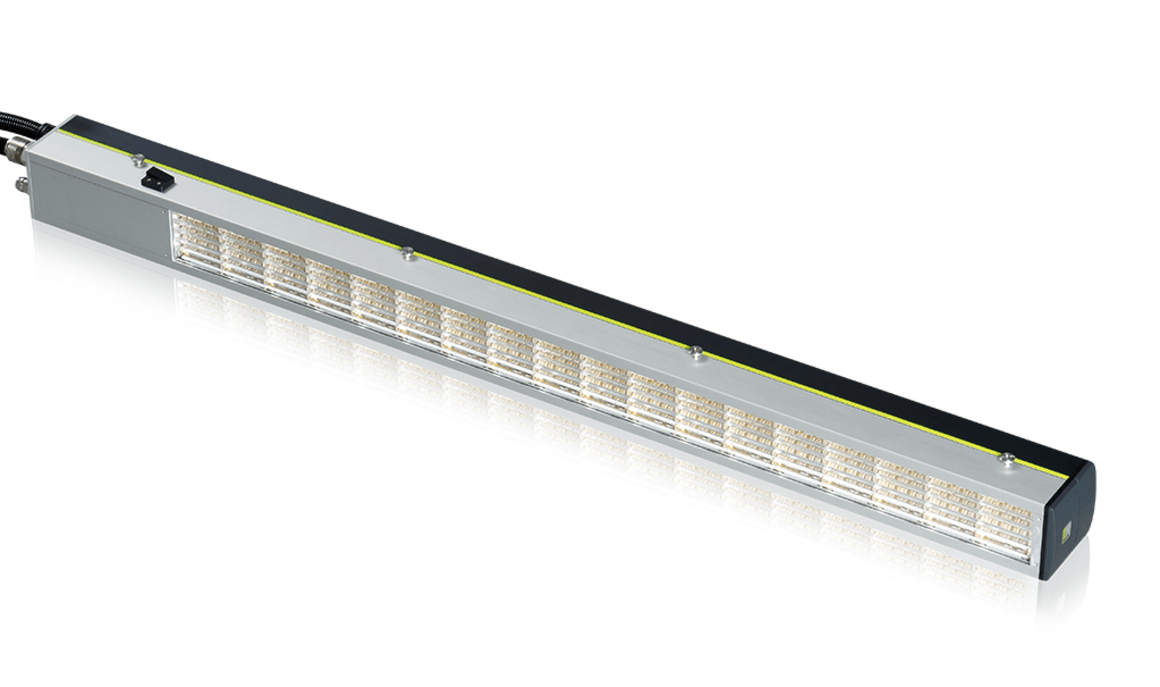

De LEDcure vervolledigt het volledige assortiment herontworpen LED-oplossingen, dat IST samen met haar dochteronderneming IST INTECH aanbiedt. Synergiën tussen de twee bedrijven komen steeds vaker tot stand, zoals XT8 Booster. Dankzij de nieuwe boostertechnologie heeft de LEDcure tot 30% meer vermogen dan conventionele LED-systemen. Andere highlights van de nieuwe LEDcure zijn de eenvoudige vervanging van de optiek of de mogelijkheid om de LED-chips achteraf aan te brengen.

Prestaties gekoppeld met flexibiliteit

Op de gebruikelijke afstand van 50 mm tot 100 mm van het substraat biedt de nieuwe LEDcure een zeer hoge prestatie in vellenoffsetdruk. Dit komt niet alleen door de maximale bestralingsintensiteit, de zogenaamde peak, maar het brede bestralingsveld van de LEDcure biedt ook een extra droogtijd, ook wel dosis genoemd. Het is vaak net zo bepalend voor een efficiënte uitharding van de LED-kleuren en lakken als de piek. Hierdoor hebben klanten en leveranciers van verbruiksmaterialen meer flexibiliteit in het ontwerp en de keuze van drukinkten, verven en lakken.